Ceramic Forming Polymers

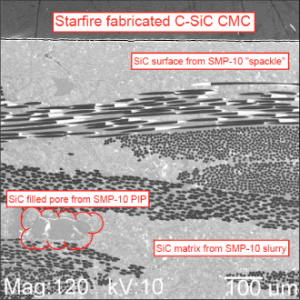

Starfire® Systems produces two families of ceramic forming polymers:

Silicon Carbide (SiC) – Polycarbosilane Based

These proprietary Starfire® Systems polymers are our original technology and yield near stoichiometric SiC ceramics when converted. They are our highest strength polymers, thermally stable to 2500°C +, and available in new, hot melt versions.

These proprietary Starfire® Systems polymers are our original technology and yield near stoichiometric SiC ceramics when converted. They are our highest strength polymers, thermally stable to 2500°C +, and available in new, hot melt versions.

Starfire’s advanced technology offers a polymer route to near stoichiometric silicon carbides, delivering the benefits of SiC ceramic composites without the sintering and machining challenges. Our polymers form a high-strength green part with cure temperatures as low as 200°C and then form SiCs with nanoscale grain sizes as low as 800°C.

Highlights:

- Ability to mold complex, near net-shaped ceramic composite components

- Features a low temperature green cure

- Ceramic is formed using low cost furnaces

- Nanoscale ceramic grain yields tough parts

- Products are flexible – they feature low viscosity for infiltration or hot melt for layups

- Materials are lightweight, corrosion resistant, and temperature resistant

- Materials increase friction while reducing wear

Applications:

- SiC ceramic matrix composite components

- Infiltrate low cost preform for enhanced performance

- Suitable for a variety of structural, thermal, or friction uses

Silicon Oxycarbide (SiOC) – Polysiloxane Based

Our silicon oxycarbide resins are Starfire® Systems’ newest technology that is specifically designed to offer a tough, durable ceramic for moderate service temperatures. Starfire® Systems’ technology produces low cost, high performance silicon oxycarbide ceramics with configurable properties.

We have the ability to customize the ratios of Si-O-C and have the most cost effective ceramic formers on the market with services up to 1200°C.

Highlights:

- Strong cost / performance value proposition

- Mold complex near net-shaped ceramic composite parts

- Composite design flexibility (e.g., 2D layup, preform, BMC)

- Green cure in conventional presses and molds

- Low cost furnaces for firing ceramic

- Configurable ratio of Si-O-C in ceramic

- Lightweight, corrosion, and temperature resistant

Applications:

- Ceramics up to 1200°C

- Oxidation protective coatings to at least 1200°C

- Ceramic Matrix forming by conventional techniques (e.g., RTM, VARTM, slip casting, infiltrating)