THE POLYMER INFILTRATION & PYROLYSIS (PIP) PROCESS

Key

![]() Starfire Matrix Forming Polymer

Starfire Matrix Forming Polymer![]() Pyrolyzed Matrix Polymer

Pyrolyzed Matrix Polymer![]() Carbon or other Fiber

Carbon or other Fiber![]() Starfire Infiltration Polymer

Starfire Infiltration Polymer![]() Ceramic Filler

Ceramic Filler![]() Pyrolyzed Infiltration Polymer

Pyrolyzed Infiltration Polymer

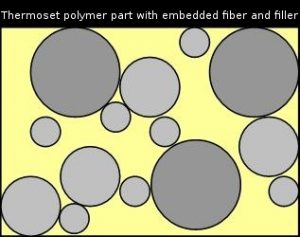

- Starfire® polymers can be formed into composite parts using traditional polymer forming processes to produce a thermoset part.

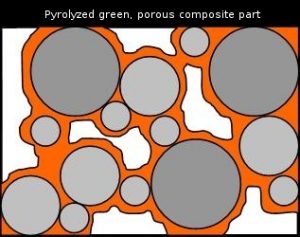

- Part is pyrolyzed to yield a porous green body (2) which is densified using polymer infiltration and pyrolysis (PIP).

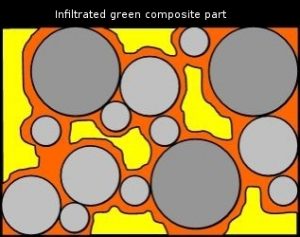

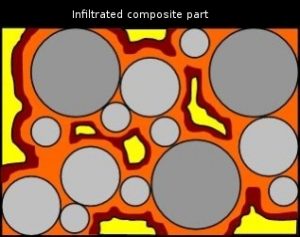

- Open porosity of the part is filled with Starfire Systems polymer using vacuum infiltration.

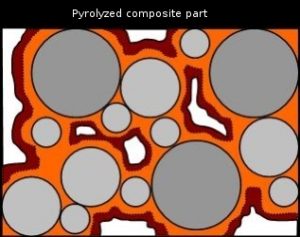

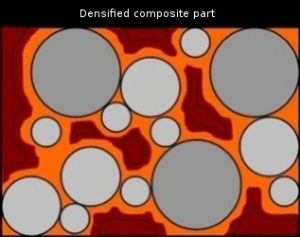

- Part is pyrolyzed in an inert environment where the polymer decomposes to a ceramic, shrinking in volume and increasing in density, such that open porosity is again created.

- Part is again infiltrated.

- Part is again pyrolyzed.

- The infiltration and pyrolysis process is repeated several times (5 and 6), until a part of the desired density is obtained. A typical number of PIP cycles is between 6 and 10, depending on final application and desired properties.